Introduction

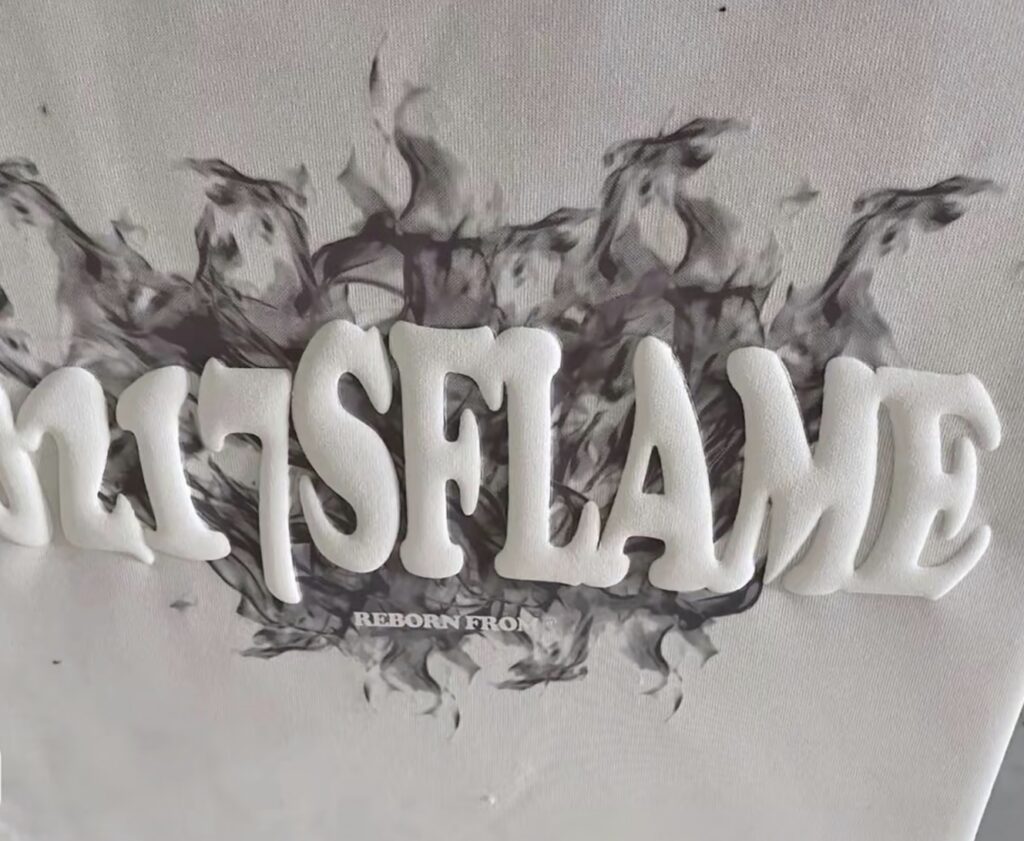

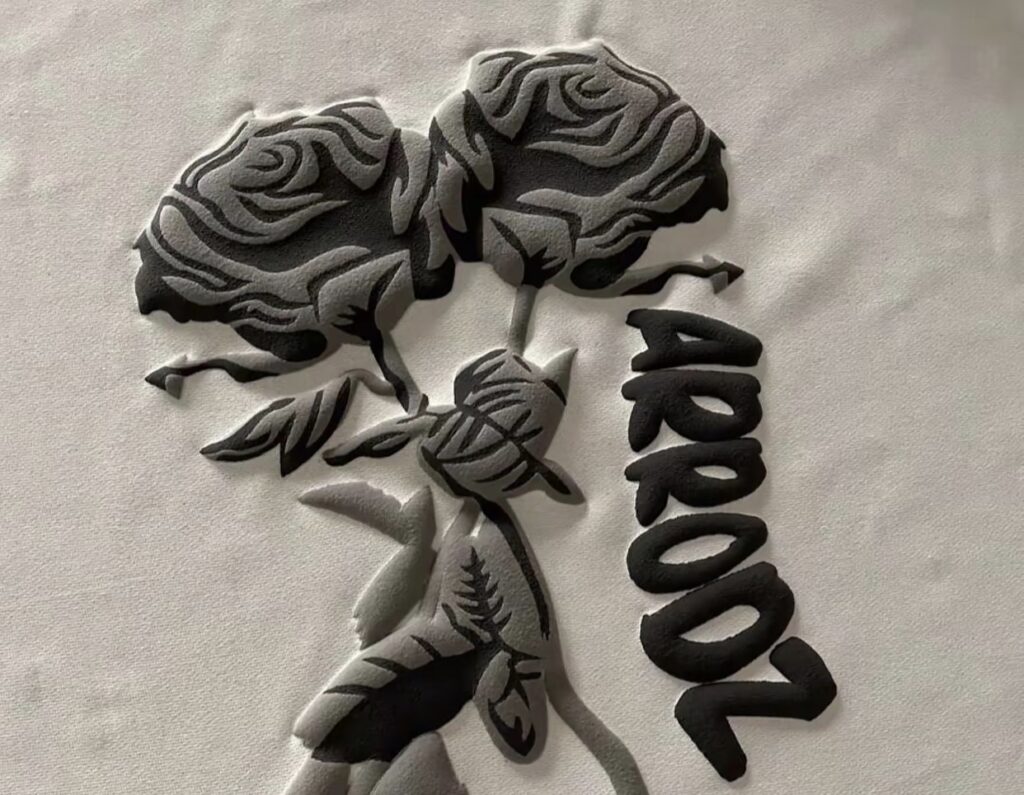

Ever touched a t-shirt design that literally pops off the fabric? That tactile, eye-catching effect is likely the magic of 3D Raised Printing, also known as Puff Printing or Foam Printing. A game-changer in the apparel decoration world, adding unique dimension and texture.

If you’re looking for standout designs for your custom tees or sportswear, understanding this technology is key. Let’s dive deep into what 3D Puff Printing is, how it works, and why it might be perfect for your next apparel line.

Demystifying the Process: How Does 3D Puff Printing Work?

At its core, 3D Puff Printing is a specialized variation of traditional screen printing. Here’s the step-by-step breakdown:

- Screen Creation: A stencil (screen) is created for the specific design element intended to be raised.

- Special Ink Formulation: Instead of standard plastisol ink, a unique puff additive is mixed into the ink base. This additive contains blowing agents.

- Ink Application: A squeegee pushes the puff ink mixture through the screen onto the garment, just like regular screen printing.

- The “Puff” Transformation: This is the crucial step. The printed garment enters a conveyor dryer. They set it to a specific, controlled temperature. Heat activates the blowing agents in the puff additive.

- When the ink heats, it swells—making the printed part puff up a lot off the fabric.

- The ink cures simultaneously, locking in the raised, textured effect as it cools.

Key Characteristics of 3D Puff Printing

- Tactile Texture: The most defining feature is the raised, rubbery feel. You can physically feel the design.

- Visual Dimension: Creates significant height and depth off the garment, offering a bold, 3D look that catches light differently.

- Soft Feel (When Cool): Once cured and cooled, the raised areas have a slightly soft, foam-like texture, not hard like plastic transfers.

- Opaque Coverage: Provides excellent opacity, even on darker fabrics, hiding the garment color beneath the print.

Why Choose 3D Puff Printing for T-Shirts and Sportswear?

This technology offers distinct advantages, especially relevant to your niche:

- High Visual & Tactile Impact: Makes designs literally “pop”, grabbing immediate attention. Ideal for logos, text, and bold graphic elements on t-shirts, hoodies, and sweatshirts.

- Enhanced Brand Perception: The unique texture shows quality, craftsmanship, and that it’s high-end. It feels substantial and expensive.

- Durability & Longevity: When cured properly, 3D prints are highly durable. They resist cracking and peeling exceptionally well, even after multiple washes – crucial for sportswear and frequently worn tees.

- Versatility on Fabrics: Works effectively on cotton, cotton blends, fleece, and sweatshirt material, the staples of casual and athletic apparel.

- Unique Design Element: Offers a differentiator in a crowded market. It gives you a feel that’s more than just how it looks.

3D Puff Printing vs. Other Popular Apparel Decorating Techniques

- vs. Standard Screen Printing: Standard prints lie flat on the fabric. 3D printing adds significant height and texture that standard printing cannot achieve.

- vs. Embroidery: Embroidery also has dimension but is a stitching process. 3D printing uses ink. It usually makes finer details and smoother color fades in the raised parts. Usually, complex multi-color designs are faster and cheaper.

- vs. Heat Transfers (DTF, Sublimation): Transfers can sometimes mimic a slight texture but rarely achieve the pronounced height and distinct “puff” feel of true 3D printing. They can also feel more like a plastic layer on top.

- vs. PVC/Rubber Screen Printing: PVC prints are thicker and harder, creating a more rigid, plastic-like feel. 3D puff is softer and more foam-like.

Design Considerations & Best Practices for 3D Prints

To get the best results:

- Simplicity is Often Key: Works best with bold outlines, text, and simpler graphic elements. Very fine lines or intricate details can sometimes become blurred or lost during the expansion process.

- Line Weight Matters: Make sure lines and shapes are thick enough. A good thickness is usually 1-2 points. This helps them puff well and stay clear.

- Color Choices: Manufacturers usually mix the puff additive into white, colored, or even clear inks. Vibrant colors work well. Getting subtle color fades in the raised area can be tricky, but good printers can pull it off.

- Underbasing: On dark garments, printers might use a white underbase layer before applying the puff ink to ensure color vibrancy, though the puff layer itself usually provides enough opacity.

Caring for Your 3D Puff Printing Apparel

Maximize the life of your awesome textured tees and gear:

- Wash Inside Out: Always turn the garment inside out before washing. This keeps the raised part from wearing down.

- Use Cold Water: Opt for cold or cool water washes. Hot water might soften the ink and mess with its shape over time.

- Gentle Cycle: Pick a soft or delicate wash setting to reduce wear and tear.

- Mild Detergent: Use a mild detergent. Avoid harsh chemicals or bleach.

- Air Dry or Low Heat: Tumble dry on low heat or, ideally, air dry. High heat can damage the puff effect.

- Skip the Iron: Never iron directly on the 3D print! The heat will melt and flatten it. If ironing is necessary, iron the garment inside out with minimal heat, avoiding the print area completely.

The Future of Dimension: 3D Printing in Fashion

While 3D Raised (Puff) Screen Printing is well-established, the term “3D Printing” in broader tech contexts often refers to additive manufacturing (building objects layer by layer).

While directly 3D printing entire complex garments onto fabric at scale is still emerging, textile 3D printing technologies are advancing rapidly.

We might see future integrations that build precise, complex 3D structures directly onto apparel, potentially merging aspects of traditional puff effects with new material possibilities.

Conclusion: Is 3D Puff Printing Right for Your Next Collection?

3D Puff Printing offers an unbeatable combination of bold visual impact, unique tactile appeal, and impressive durability. For t-shirt brands, sportswear lines, or any apparel business looking to create standout pieces that customers love to touch as much as look at, it’s a powerful tool.

While best suited for specific design styles (bolder elements), its ability to convey quality and create a memorable sensory experience makes it a valuable technique in the custom apparel decorator’s arsenal. When you want your designs to literally rise above the competition, 3D puff printing delivers.