China is a top global choice for garment manufacturing.

The country has a comprehensive industry system, efficient supply chain, and strong innovation.

As the world’s largest producer and exporter:

- It makes over 70 billion garments yearly (50% of global output)

- Exported $182 billion worth of clothing in 2022 (31.7% global share)

Its nationwide production clusters cover everything from design and production to logistics. This supports both international brands and Chinese brands expanding globally.

China consistently delivers quality, speed, and responsible manufacturing.

We will deep dive into China’s top ten clothing manufacturers.

1.Esquel Group

- Introduction:

- Founded in 1978 and headquartered in Hong Kong, Esquel is a leading global textile and apparel enterprise.

- This manufacturer operates a vertically integrated supply chain,covering everything from cotton farming to garment production.

- Workforce of approximately 80,000 employees

- Annual production capacity of nearly 100 million shirts

- Core Business: Garment production: Shirts, casual wear, especially high-end shirts.

- Core Values:

- Mission: To be clients’ “best pure cotton shirt partner”.

- Principle: A contented workforce ensures client contentment.

- Commitment: Provide “one-stop shirt services” and promote sustainable development.

Strengths & Weaknesses:

- Strengths:

- Vertically integrated supply chain ensures quality and efficiency;

- Leading waterless dyeing technology with significant environmental advantages;

- Digitized production shortens the production cycle to 2-3 weeks (regular orders), with the fastest delivery in 7 days.

- Weaknesses:As a large enterprise, it may lack flexibility and respond slowly to rapid market changes.

| Indicator | Details |

| Production Cycle | Regular garment orders 2-3 weeks,Fast-response orders 7 days,Customized orders 4-6 weeks |

| Shipping time: | ①Regular garment orders:Sea freight to US West Coast: 20-25 days;air freight to Europe: 8-12 days ②Fast-response orders:Air freight to North America/Europe: 5-7 days ③Customized orders:Sea freight to US East Coast: 28-35 days; air freight globally: 7-10 days |

| Core Advantages | ①Fully integrated supply chain from cotton to finished garments, ensuring stable quality. ②Innovative eco-friendly technology: Waterless dyeing with over 97% color fixation rate. ③Digitized production: Automated equipment and AI management systems improve efficiency. |

2.Shenzhou International

- Introduction:

- World’s largest vertically integrated knitwear manufacturer (since 1988)

- Key OEM partner: Supplies Uniqlo, Nike, and other global brands

- Revenue: Exceeds ¥20 billion annually

- Global production: 55% capacity overseas (Vietnam, Cambodia)

- Core Business: Provides ODM/OEM manufacturing services for:

- Sportswear (60% of revenue)

- Underwear

- Casual wear

- Core Values: Customer-first, quality-first, continuous innovation.

Strengths & Weaknesses:

- Strengths:

- Scale advantage: Daily output: 500,000+ pieces per factory

- Fabric innovation: Develops 300+ new fabrics yearly

- Risk resilience:Multi-regional production bases

- Weaknesses: Lack of self-owned brands (95% revenue from OEM), sensitive to labor costs (25% of costs in Southeast Asian factories).

| Indicator | Details |

| Production Cycle | 45 days for regular orders (full industrial chain), 15 days for rush orders (with sufficient materials). |

| Shipping time: | 3-5 weeks for major global markets (2-3 weeks for Southeast Asia via local factories). |

| Core Advantages | ① Full industrial chain integration (self-developed fabrics like Coolmax); ② Strict quality control (ISO9001, WRAP certified); ③Deeply bind with customers(top 5 clients contribute 85% revenue). |

3.Jiangsu Chenfeng Group

- Introduction:

- Founded: 1967

- Headquarters: Changzhou, Jiangsu

- Sustainability: Member of the Sustainable Apparel Coalition (SAC)

- Production Bases: → 5 garment production facilities,→ 2 textile manufacturing bases

- Core Business:Garment manufacturing: Shirts, casual wear, sportswear, especially good at silk and cotton-linen products.

- Core Values:

- Vision: To be China’s most competitive textile and apparel ecosystem.

- Core philosophy: Uphold personal integrity and professional dedication.

Strengths & Weaknesses:

- Strengths:

- Efficient full-industry-chain service model, quickly responding to custom needs

- University cooperation enhances design capabilities for high-value transformation.

- Weaknesses:

- Declining order volume in recent years (from 260,000 to 200,000 pieces daily);

- Faces low-price competition pressure; relies heavily on overseas markets, affected by trade policies.

| Indicator | Details |

| Production Cycle | Regular orders:3-4 weeks Small-batch fast-response orders:7-10 days Complex customized orders:6-8 weeks |

| Shipping time: | ①Regular orders:Sea freight to Europe: 30-40 days; air freight to Japan: 3-5 days ②Small-batch fast-response orders:Air freight to North America/Europe: 8-12 days ③Complex customized orders:Sea freight to the US: 25-30 days; air freight globally: 10-14 days |

| Core Advantages | ①Full-industry-chain integration from fabric R&D to garment production, improving efficiency. ②Design innovation: Collaborates with universities to drive product differentiation. ③Sustainability: Carbon labeling covers 98% of products, meeting international eco-standards. |

4.Ceknoclothing

- Introduction:

- Market Coverage: North America, Western Europe, Middle East, Australia.

- Client Types: Luxury brands, wholesalers, fast fashion, online shops, other retailers.

- Core Business: The company produce T-shirts, hoodies, sweatshirts, sweatpants, and coordinated sets.

- Core Values:

- Employees as family: Fostering a supportive workplace

- Customers as lifelong partners: Building enduring relationships

- Quality commitment: Delivering high-value apparel through consistent craftsmanship

Strengths & Weaknesses:

- Strengths:

- Ceknoclothing deliver integrated supply chain solutions: Design → Production → Quality Control ,End-to-end Logistics & Door-to-Door Delivery

- Market Advantages: Flexible MOQs & Customized Inventory,Cost-Efficient Operations, Global Distribution Network

- Weaknesses:

- Production constraints: Large-scale customization demands longer lead times

- Market dynamics: Intense competition in adult apparel + demanding younger consumers

- Growth limitation: Slow international expansion

| Indicator | Details |

| Production Cycle | 15-20 days for large orders, 3-7 days for customized orders. |

| Shipping time: | supports sea, land, and air transportation, air transportation takes 13-15 days, sea transportation takes 30-45 days, and Luyunqing takes 20-30 days. |

| Core Advantages | supports full customization including fabrics, patterns, embroidery, patterns, and micro customization for quick sampling and delivery |

5.Crystal International Group

- Introduction:

- Founded: 1970

- Headquarters: Hong Kong

- Business: Global apparel manufacturing partner

- Factories: 23 in 5 countries (e.g., Vietnam, China)

- Employees: 70,000 globally

- Production: Makes over 470 million clothes yearly

- Main Clients: Uniqlo, Nike, Levi’s

- Core Business: Garment manufacturing: Five categories including casual wear, denim, underwear, sportswear.

- Core Values:

- Sustainable development: Aims for net-zero carbon by 2050, promotes green production.

- Innovation-driven: Going digital and automation improve efficiency, develops eco-friendly washing technology.

Strengths & Weaknesses:

- Strengths:

- Co-creation model cuts production cycle from 12 weeks to days;

- Over 60% capacity in Vietnam brings cost advantages; leads the global denim market share.

- Weaknesses:

- Over-reliance on Vietnam’s capacity faces politics risks;

- Lower unit output value than industry average, with thin profit margins.

| Indicator | Details |

| Production Cycle | Basic T-shirts:7-10 days Denim wear:10-14 days Custom sportswear:3-4 weeks |

| Shipping time: | ①Basic T-shirts:Sea freight to US West Coast: 12-15 days; land transport to Southeast Asia: 3-5 days ②Denim wear:Sea freight to US East Coast: 25-28 days; air freight to Europe: 7-10 days ③Custom sportswear:Sea freight to major global ports: 20-25 days; air freight to North America: 5-7 days |

| Core Advantages | ①Co-creation model: From design to delivery in days, quickly responding to market needs. ②Vertical integration: In-house fabric mills reduce costs and improve self-supply. ③Sustainable practices: Eco-friendly washing technology reduces pollution, promotes circular economy. |

6.Modaknits

- Introduction:

- Modaknits is an enterprise focused on producing high-quality rayon fabrics.

- Modaknits is committed to meeting strict industry standards through sustainable production practices.

- It give priority to rigorous quality control, adhering to top global brands’ standards to ensure excellence in every product.

- Core Business: Develops and produces rayon fabrics. Focuses on eco-friendly knitted fabrics for various uses.

- Core Values:

- Quality First: Ensure product performance through strict production processes and industry standards.

- Sustaining ability Development: Adopt eco-friendly materials and production processes, and obtain relevant ability to last certifications.

- Customer-Oriented: Support the needs of brands and designers through quick response and customized services.

Strengths & Weaknesses:

- Strengths:

- Technical Capabilities: Possess advanced knitting technology and quality control systems, supporting a fast production cycle of 15-25 days.

- Sustainability Certifications: Products meet international environmental standards like OEKO-TEX, enhancing market ability to compete.

- Customer Resources: Has long-term partnerships with international brands like ZARA and VERO MODA, ensuring stable supply chains.

- Weaknesses:

- Little transparency: The company doesn’t clearly share its background, how it makes products, or shipping rules on its website. This damages customer trust.

- Uncertain Shipping Time: International shipping time relies on third-party logistics (e.g., DHL) without standardized timeliness descriptions.

- Limited Market Coverage: Mainly serving B2B clients, with low awareness among end consumers.

| Indicator | Details |

| Production Cycle | 15-25 days (referencing the fast delivery cycle of partner enterprise Weisman). |

| Shipping time: | International shipping usually takes 3-6 days (estimated based on industry standards for fabric import shipping). |

| Core Advantages | ①Sustainable Production: Use of eco-friendly materials with OEKO-TEX and other certifications. ②Quick Response: Support urgent order delivery within 15-25 days. ③Quality Control: Strict production processes aligned with international brands. |

7.Mgoofashion

- Introduction:

- Founded in 2012 and headquartered in Beijing, China, it’s a clothing customization manufacturer offering one-stop services.

- It serves over 4 million wealthy users, has 3+ million products online, and an average order over 3,000 RMB.

- Core Business: Custom clothing maker: Provides full services from design to shipping, supports ODM (adds 50+ new styles weekly), and helps brands grow.

- Core Values:

- Quality First: Partners with China Inspection Group’s luxury verification center, vets merchants strictly, and requires high deposits. Guarantees all products are real, with 3x compensation for fakes.

- It helps with custom needs for top products using style advisors, VIP service teams, and buyer-based service.

- Innovative: Uses data and AI to better the supply chain, speed up sales, and add new services like live sales and overseas storage.

Strengths & Weaknesses:

- Strengths:

- Guaranteed Veracity: Partners with certified veracity, enforces rigorous merchant vetting and compensation policies to build user trust.

- Streamlined Operations: Our SaaS system manages multiple product codes, enables real-time inventory checks, and single-item verification for faster order fulfillment.

- Loyal Premium Clientele: Attracts high-value users (average order >¥3,000) with strong repurchase rates, primarily serving affluent shoppers.

- Global Sourcing Network: Connects with worldwide buyers for 1,600+ brands, providing exclusive access to rare and limited-edition items

- Weaknesses:

- Delivery Delays: Some users experience long international shipping times (7-21 days) and potential customs delays.

- Inconsistent After-Sales: Complaints cite inefficient handling of issues (e.g., defects, missing items) and slow customer service response.

- Purchasing Agent Issues: Quality varies among buyers, with some users reporting un professional affecting purchase confidence.

| Indicator | Details |

| Production Cycle | Custom clothing: 15-30 days based on order complexity, with expedited options (7-10 days). In-stock items: Orders from Mgoofashion (M Cheng) warehouse can be shipped within 24 hours after confirmation. |

| Shipping time: | ①Domestic delivery: 3-7 days via standard express, 1-3 days via expedited service. ②International shipping: 7-15 days to Europe and America, 5-10 days to Asia, up to 21 days for remote areas (including 1-3 days of customs clearance). |

| Core Advantages | ①End-to-end service capability: One-stop solutions from design to delivery, reducing brand operation barriers. ② Data-driven product selection: Analyzes fashion trends through big data to precisely match user needs and boost best-seller rates. ③ Dual guarantee of authenticity and service: China Inspection authentication + platform pre-compensation, combined with fashion consultant services, to build a differentiated trust barrier. |

8.Arlisman

- Introduction:

- Arlisman focuses on wholesale and retail of clothing.

- Arlisman also produces custom knitwear (e.g., T-shirts, Polo shirts) as an OEM/ODM supplier, taking ~13–14 weeks per order.

- Core Business: Focuses on OEM production of knitwear (T-shirts, Polo shirts, casual wear) with support for small-batch orders

- Core Values:“fast delivery” and “high-quality customization”

Strengths & Weaknesses:

- Strengths:

- Flexibility: Supports small-batch orders, ideal for cross-border e-commerce and brand clients.

- Logistics Efficiency: Emphasizes “global fast shipping,” leveraging platforms like Aliba ba.com for optimized delivery.

- Weaknesses:

- Long Production Cycle: Standard cycle of 13-14 weeks may not meet urgent order needs.

- Intense Competition: Uniform market requires distinction via price or design.

| Indicator | Details |

| Production Cycle | Small-batch orders (800+ pieces): ~13-14 weeks; expedited service: 7-10 days. |

| Shipping time: | International: 3-5 working days via DHL, 4-7 days via UPS-Saver (through Alibaba logistics). |

| Core Advantages | ①Flexible small-batch customization. ②Global fast shipping with wide logistics coverage. ③High efficiency via cross-border e-commerce platforms. |

9.Luenthai

- Introduction:

- Founded in 1965

- Based in Hong Kong

- Global clothing maker

- Also in retail, logistics, real estate

Core Business:

- Full-process coverage: Design → Fabric development → Production → Logistics

- Apparel categories: Casual wear, sportswear, women’s fashion & more

- Core Values:

- Customer-first approach

- Vision: “Become the world’s best clothing manufacturer”

Strengths & Weaknesses:

- Strengths:

- Integrated Supply Chain

- Fast Market Response

- Advanced Tech & Equipment

- Efficient Logistics

- Weaknesses:

- Higher Costs

- Brand Dependency

- Growing Competition

| Indicator | Details |

| Production Cycle | Design cycle:7 days Production cycle:15 days (From fabric procurement to finished garments, including 26 processes like cutting, sewing, ironing). |

| Shipping time: | 1-2 days (Direct delivery to global stores via integrated logistics, saving intermediate sorting). |

| Core Advantages | ①D2S one-stop service model ②Supply chain collaboration ③Smart manufacturing & digitalization ④Global layout ⑤Deep cooperation with brands |

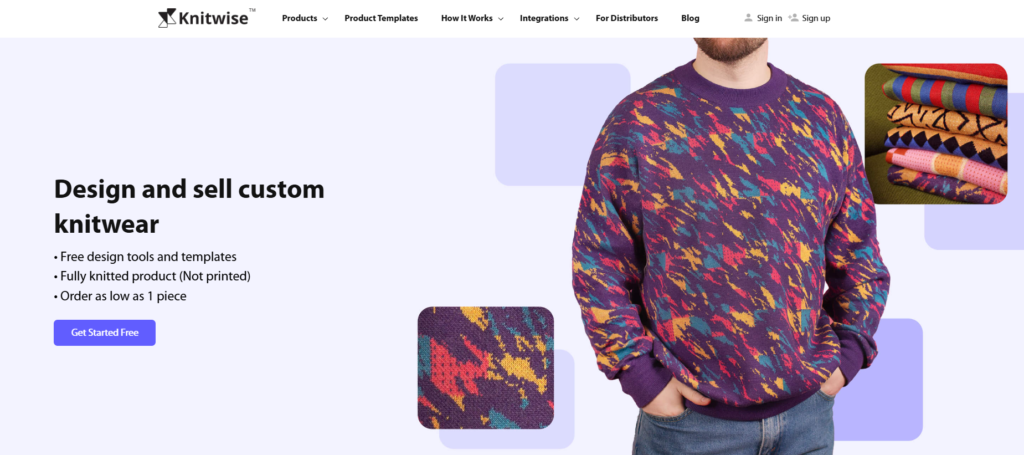

10.Knitwise

- Introduction:

- Canadian online custom knitwear platform

- Founded 2003 | Based in Ottawa

- Core: Print-on-demand model (zero inventory)

- Serves: Individual + corporate clients

- Full process: Design → Production → Sales

Core Business:

- End-to-end service: Design → Finished products

- Products: Sweaters, scarves, hats & more

- Custom options: Patterns / Sizes / Fabrics

Core Values:

- Sustainability:→ On-demand model cuts waste & excess stock. → Eco-friendly manufacturing

- Customer Empowerment:→ Easy-to-use design tools. → Helps creators/small businesses sell their designs

- Technological Innovation: → Digital production tools. → Shortens design→delivery time

Strengths & Weaknesses:

- Strengths:

- Zero inventory risk: → No pre-purchase inventory. → Lowers financial burden

- High customization capability: → Full custom designs. → Meets specialized market needs

- Technical integration:→ Design tools linked to production. → Speeds up workflow

- Sustainable practices:→ Precise manufacturing = less waste. → Eco-friendly approach

- Weaknesses:

- Low brand awareness: → Limited website traffic. → Low market visibility

- Dependence on logistics partners:→ Relies on outside shippers. → Slow delivery hurts satisfaction

- Price competitiveness: → Costly custom services. → Pricier than mass-produced items

| Indicator | Details |

| Production Cycle | Regular orders: 5–10 working days (including design confirmation); Urgent orders: 3–5 working days. |

| Shipping time: | ①Local (Canada): 3–7 days (express delivery) ②International: 7–21 days (air freight) or 20–30 days (sea freight). |

| Core Advantages | ①On-demand production model: Zero inventory risk, flexible for small-batch orders. ②Tech-driven customization: Seamless integration of design tools and production systems for quick iteration. ③Sustainability: Precise production reduces waste, meeting ESG standards. |