Colorfastness is a crucial aspect of custom apparel printing, as it determines how well the fabric color stays intact after washing, exposure to light, and general wear. For anyone in the custom apparel industry, understanding how to manage colorfastness is vital to creating high-quality, long-lasting products. This article explores the factors affecting colorfastness, how to test it, and the best practices for ensuring it in your custom clothing.

1. What is Colorfastness and Why Does It Matter?

Colorfastness refers to a fabric’s ability to retain its color without fading or bleeding when exposed to various conditions. In custom apparel printing, poor colorfastness can lead to:

- Fading fabric colors after washing or sunlight exposure.

- Color transfer onto other garments or fabrics.

- Customer dissatisfaction, leading to returns or negative reviews.

For businesses offering custom clothing, ensuring high colorfastness is key to maintaining product quality and customer trust.

2. Factors Affecting Colorfastness

Several elements impact how well a fabric holds its color:

- Fabric Type: Natural fibers like cotton may need extra treatments to retain color, while synthetics like polyester generally hold color better.

- Printing Technique: Different printing methods, such as screen printing or heat transfer printing, yield different results in terms of color durability.

- Dye Quality: The type of dye used (e.g., reactive dyes vs. disperse dyes) plays a significant role in color retention.

- Fabric Preparation: Proper preparation, like pre-washing or treating fabrics, helps improve dye absorption and colorfastness.

3. Printing Techniques and Their Impact on Colorfastness

The printing method you choose will directly affect the colorfastness of your custom apparel. Here’s how some of the most common printing techniques stack up:

- Screen Printing: One of the most popular printing methods for custom clothing, screen printing offers excellent durability and vibrant screen prints. This technique works especially well on heavier fabrics and provides long-lasting color, even after multiple washes.

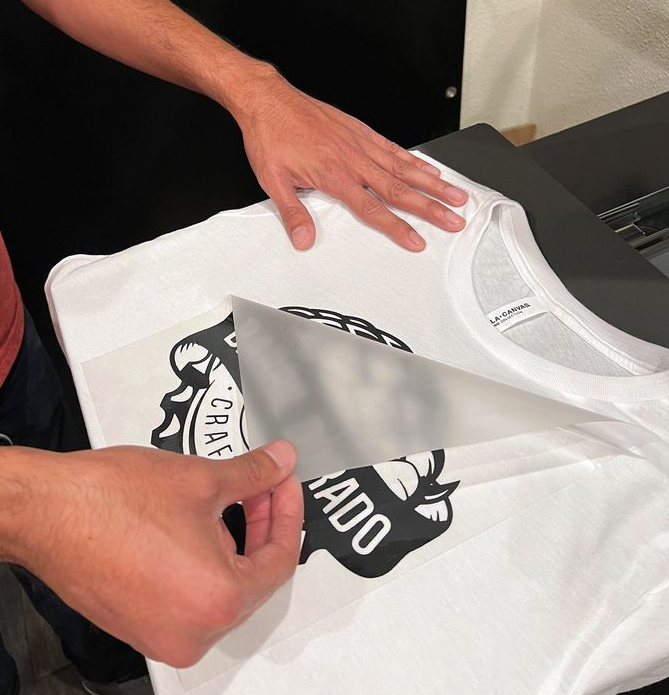

- Heat Transfer Printing: Heat transfer printing uses heat and pressure to transfer a design onto fabric. While it’s a cost-effective choice for smaller batches or intricate designs, it may not offer the same level of colorfastness as screen printing, particularly on fabrics with a lot of wear and tear.

- Sublimation Printing: Best suited for polyester or polyester-blend fabrics, sublimation printing involves turning dye into gas and embedding it into the fabric. This method results in highly vibrant, durable prints that are resistant to fading. However, it works best on light-colored fabrics and doesn’t perform as well on natural fibers.

Tip: Choosing the right printing method is crucial for achieving high-quality custom apparel printing with lasting color.

4. How to Test Colorfastness

Before committing to bulk orders, it’s essential to test the colorfastness of your prints. Here are some simple tests you can perform:

- Rubbing Test: Rub a damp white cloth on the printed design to check for any color transfer. If the color rubs off easily, the fabric may not have adequate colorfastness.

- Washing Test: Wash a sample piece in cold water and check for fading or bleeding. This will give you a clear idea of how the fabric color holds up after washing.

- Light Exposure Test: Place the fabric under direct sunlight for several hours to observe any fading or discoloration.

5. Best Practices for Ensuring Colorfastness

To ensure your custom apparel maintains its color over time, follow these best practices:

- Select the right fabric: Choose fabrics that suit the printing method and are known for better color retention, such as polyester for sublimation printing or treated cotton for screen printing.

- Choose high-quality inks and dyes: Invest in good quality dyes and inks that are designed for durability.

- Work with an experienced printer: A reputable printer will use proper techniques to ensure the ink adheres well to the fabric and that colorfastness is prioritized.

- Offer care instructions: Advise your customers on how to properly care for their apparel to maintain the color, such as washing in cold water and avoiding direct sunlight.

Conclusion

Understanding colorfastness is essential for producing high-quality, long-lasting custom clothing. By selecting the right printing methods, fabrics, and dyes, you can ensure vibrant, durable designs that stand the test of time. Whether you’re using screen printing, heat transfer printing, or sublimation printing, following best practices will help you deliver products that meet customer expectations.