Have you ever admired a sharp graphic on a t-shirt, a shiny logo on a hoodie, or detailed lettering on a sports jacket? Chances are high you were looking at the magic of Vinyl Heat Transfer (HTV). As a tool transforming blank garments into personalized statements, HTV is the powerhouse behind countless custom apparel pieces. Let’s dive deep into what it is, how it works, and why it’s a game-changer for your clothing line or DIY projects.

What Exactly Is Heat Transfer Vinyl?

People also know Heat Transfer Vinyl (HTV) as iron-on vinyl or T-shirt vinyl. Designers use a special material to make designs on cloth. Think of it as a thin, flexible plastic film (the vinyl) coated with a heat-activated adhesive on one side. This film comes covered by a carrier sheet (often clear or paper-like) that protects it during cutting and weeding.

How Does Vinyl Heat Transfer Actually Work?

The “heat transfer” aspect is crucial to the process. Using HTV is not just about sticking it on.

It needs controlled heat and pressure. This makes the glue work and sticks it to the cloth fibers for good.

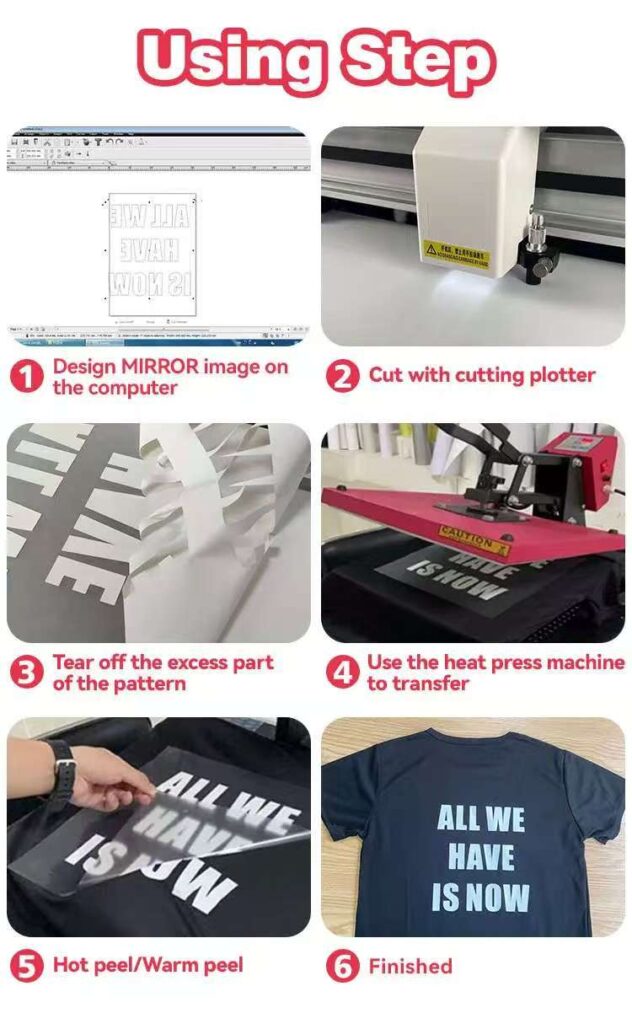

- Design & Cut: We create your design digitally.

- Weeding: After cutting, you carefully remove the extra vinyl around and inside your design.

- Positioning (Mirroring is Crucial!): The designer places the weeded design (still on its carrier sheet) adhesive-side down onto the fabric.

- Key step: Designers need to cut most designs backwards so they look right when transferred.

- Pressing: Use a heat press for the best results.

- Peeling (Hot or Cold): After pressing, you either:

- Hot Peel: Immediately peel the carrier sheet away while the vinyl is still hot (common for some types).

- Cold Peel: Let the vinyl cool completely before removing the carrier sheet (required for many types to prevent distortion).

Unveiling the Spectrum: Major Types of Heat Transfer Vinyl

HTV isn’t one-size-fits-all. Different types create distinct looks and textures:

- Standard/Premium HTV: Your workhorse. Offers excellent color coverage and durability. Great for most designs. (e.g., Siser EasyWeed, Oracle 651).

- Glitter HTV: Features a dazzling glitter finish embedded in the vinyl. Adds serious sparkle and texture. (e.g., Siser Glitter, Thermoflex Glitter).

- Metallic HTV: Provides a shiny, reflective foil-like finish (gold, silver, rose gold, etc.). Perfect for elegant or eye-catching accents.

- Glow in the Dark HTV: Absorbs light and emits a cool glow in darkness. Fantastic for safety wear or fun nighttime designs.

- Puff / 3D HTV: Expands (puffs up) during pressing, creating a unique raised, textured effect. Great for adding dimension.

- Patterned HTV: Comes pre-printed with designs like camo, floral, leopard print, or woodgrain.

- Flocked HTV: Mimics the soft, velvety feel of embroidery. Creates a luxurious tactile experience.

- Sublimation HTV: Allows transferring full-color photographic prints onto garments using a sublimation printer and special HTV carrier sheets.

Why Choose Vinyl Heat Transfer?

HTV’s popularity is no accident. It offers significant benefits for businesses and hobbyists:

- Professional, Bright Results: Creates clear lines, strong colors, shiny metallics, and unique textures that are hard to beat.

- Durability: When applied correctly, HTV designs are highly resistant to cracking and fading, surviving numerous washes.

- Versatility: Works on many types of fabrics. This includes cotton, polyester, cotton/poly blends, canvas, denim, and some wood or metal. Also perfect for bags, caps, and home decor.

- No Minimums: Ideal for one-off custom pieces, small batches, or large runs. No screen setup fees.

- Relatively Fast Production: Once mastered, the design-to-press workflow is efficient, especially for multi-garment runs.

Considering the Flip Side: Potential Drawbacks of HTV

While powerful, HTV has some considerations:

- Feel: Unlike dye-sublimation or some prints, HTV sits on top of the fabric.

- Breathability: A solid layer of HTV doesn’t breathe like fabric. For large coverage areas on performance wear, dye-sublimation might be preferable.

- Learning Curve: Mastering weeding techniques, the right temperature, time, pressure settings, and peel methods takes practice. This helps to avoid mistakes like scorching or poor adhesion.

- Waste: The weeding process generates vinyl scraps, though efficient nesting in design software can minimize this.

Creative Applications for Your T-Shirts, Hoodies & More

HTV (heat transfer vinyl) offers more than just logo applications! Unleash your creativity:

- Custom Apparel: T-shirts, hoodies, sweatshirts, tank tops, leggings, kids’ clothing, sports jerseys.

- Hats & Bags: Custom baseball caps, tote bags, backpacks, drawstring bags.

- Home Decor: Pillows, tea towels, table runners, canvas wall art.

- Accessories: Custom shoes, headbands, scrunchies, patches.

- Layering: Combine different vinyl types (e.g., glitter on metallic, puff layered over color) for stunning effects.

HTV vs. The Competition: Screen Printing and Dye Sublimation

- HTV vs. Screen Printing: Screen printing excels for large runs of simple designs (few colors) on cotton, offering a softer feel. HTV wins for small batches, multi-color designs without color limits, complex artwork, and garments where screen printing setup is impractical (like finished bags).

- HTV vs. Dye Sublimation: Sublimation dyes the fabric itself, resulting in a super soft feel with no texture and excellent breathability – ideal for all-over prints on white/light polyester. However, it doesn’t work on cotton or dark fabrics. HTV works on cotton and darks, offers unique textures (glitter, puff), but has a more noticeable feel.

Mastering the Craft: Essential Tips for Flawless HTV Application

- PREP IS KING: Always pre-press your garment to remove moisture and wrinkles before applying vinyl.

- Pressure Matters: Ensure firm, even pressure across the entire design. A quality heat press is vastly superior to an iron for this.

- Perfect Peel: Follow the hot peel or cold peel instructions exactly as specified for your vinyl type. Peeling incorrectly can ruin the transfer.

- Wash Smart: Turn the garment inside out and wash in cold water. Tumble dry on low heat or air dry for maximum longevity. Avoid harsh detergents and bleach.

- Test First: Always do a test press on a scrap piece of the same fabric if possible.

Trends in Heat Transfer Vinyl

The HTV world is constantly innovating:

- Eco-Friendly Options: Increased demand for recycled vinyls and more sustainable carrier sheets.

- Softer Feels: Development of new formulations that mimic the hand-feel of printed or sublimated designs more closely.

- Special Effects: Expansion of unique textures and finishes (like holographic, color-shift, reflective beyond safety wear).

- Enhanced Durability: Vinyls becoming even more stretchable, crack-resistant, and wash-fast.

- Smart HTV: Exploration of vinyls incorporating conductive elements for wearable tech integration (early stages).

Frequently Asked Questions (FAQs) About Vinyl Heat Transfer

- Q: Is vinyl heat transfer permanent?

- A: Yes, if you use HTV correctly and follow the manufacturer’s instructions, it will bond permanently with the fabric. It can handle many washes.

- Q: Is HTV compatible with 100% cotton fabrics?

- A: Absolutely! 100% cotton is one of the best and easiest fabrics to apply most types of HTV to. Just ensure you use the correct temperature settings.

- Q: Can HTV be applied to polyester materials?

- A: Yes, but caution is needed. High temperatures can melt or scorch polyester. Always use the lower temperature range recommended by the HTV manufacturer for polyester or blends.

- Q: What’s the difference between HTV and adhesive vinyl (like Oracle 631)?

- A: HTV features a heat-activated adhesive and designers specifically create it for fabrics. Adhesive vinyl, also known as permanent vinyl, has a sticky back. It sticks when you press it down. This type of vinyl is meant for hard, smooth surfaces like walls, mugs, or laptops.

- Q: What causes HTV to peel or crack after application?

- A: Common causes include:

- – Not enough temperature, pressure, or time during pressing.

- – Using the wrong peel method (hot or cold).

- – Applying to the wrong fabric (like waterproof coatings).

- – Improper washing or drying.

- – Using low-quality vinyl.

Unleash Your Apparel Potential with Vinyl Heat Transfer

Vinyl Heat Transfer is more than just a craft supply; it’s a powerful, accessible technology empowering designers, small businesses, and hobbyists to create stunning, durable custom apparel and products.

By understanding the different types, mastering the application process, and embracing its creative potential, you can transform blank T-shirts, hoodies, sportswear, and countless other items into unique, high-quality creations that stand out in the market and delight customers.