Screen printing (also called silk screening) is a key way to print designs on clothes.

- Making custom items like t-shirts, hoodies, and sportswear is especially important.

- Where you need many copies is best for large orders

- The designs last a long time and are highly durable.

- The colors look bright and strong.

- Printing many items makes it cheaper.

Even though digital printing is newer and often discussed, screen printing is still the most reliable choice for brands that want these things.

But how exactly does this decades-old technique work its magic on your favorite garments? Let’s examine the underlying mechanisms.

How Does the Screen Printing Process Actually Work?

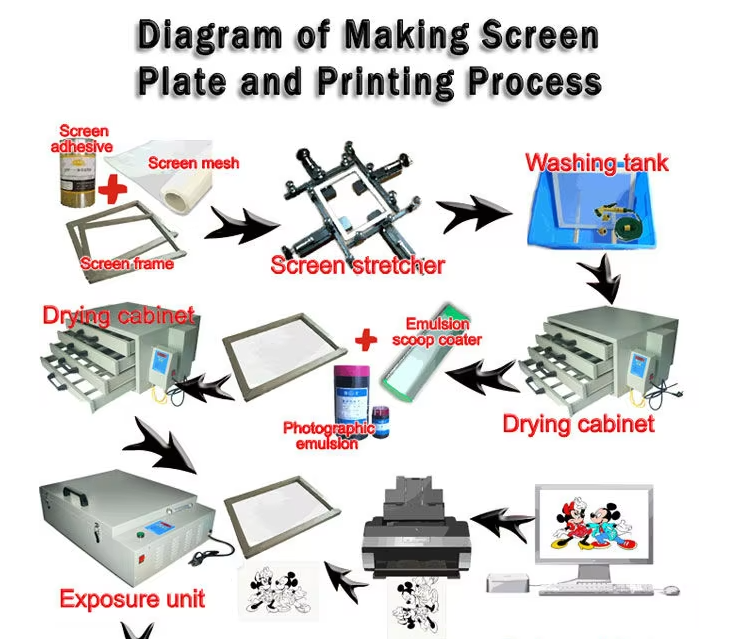

Think of it like a sophisticated stencil system. Here’s the step-by-step breakdown:

- Design & Separation: Your artwork is digitally separated into individual color layers. Each color requires its own screen. Complex designs mean more screens!

- To prepare the screen: A fine mesh screen (once made of silk, but now usually polyester) is coated with a special liquid that reacts to light. This coating then dries in the dark.

- Exposure: You place a film positive on the screen. Powerful UV light hardens the emulsion except where the design blocks it. The unhardened areas wash away, creating precise stencil openings.

- Setup & Registration: The printer mounts the prepared screen on a press. For multi-color designs, operators align (register) the screens perfectly so colors layer correctly. This is critical for crisp results.

- Printing:

- The garment (e.g., your cotton t-shirt or polyester sports jersey) is loaded onto a platen.

- The printer lowers the screen. Then they apply specialized ink to the top.

- Pull the squeegee firmly across the screen. This pushes ink through the open parts of the design and onto the fabric underneath.The screen lifts.

- Curing:The printed ink is wet. To make the print last through washing, heat-set it. Operators typically run the garment through a conveyor dryer at high heat (about 320°F / 160°C). This melts plastisol inks or evaporates water from water-based inks, bonding them to the fabric fibers.

- Why Mesh Count Matters:

- Screen mesh density (measured in threads per inch) directly impacts print quality.

- Low mesh counts (110-160) allow heavier ink deposits for bold underbases or specialty inks.

- High mesh counts (200-355) enable finer details and smoother gradients.

- Sportswear brands often use dual-density meshes – lower for opaque whites on dark fabrics, higher for color layers.

Why Is Screen Printing So Popular for T-Shirts and Sportswear?

Its dominance isn’t accidental. Key advantages drive its use:

- Unmatched Durability & Washability: Screen printed inks sit on top of the fabric, forming a thick, resilient layer. The polymer structure in plastisol inks resists wash damage. They don’t fade or crack easily, making them perfect for team uniforms and workwear.

- Vibrant Color & Opacity: Screen printing excels at laying down bold, opaque colors. It easily prints bright whites, deep blacks, and vivid hues on dark garments – something many digital methods struggle with. Metallic and specialty inks also shine.

- Cost-Effectiveness for Volume: Setting up screens and color separations costs money upfront, but printing more units makes each one much cheaper. For orders of dozens or hundreds+, screen printing is often the most economical choice.

- Fabric Versatility: It works exceptionally well on standard cotton t-shirts and blends. Specialized inks also allow printing on performance fabrics like polyester sportswear without sacrificing stretch or breathability significantly.

- Consistency & Speed: Once set up, a well-tuned press can produce hundreds of identical, high-quality prints per hour.

Screen Printing vs. Digital Direct-to-Garment (DTG): Which Wins?

Don’t assume one replaces the other! They serve different needs:

| Feature | Screen Printing | Direct-to-Garment (DTG) |

|---|---|---|

| Best For | Bulk orders (25+ units) | Low quantity (1-20 units), prototypes |

| Design Detail | Good (limits on fine detail/photo) | Excellent (photographic quality) |

| Color Vibrancy | ★★★★★ (Especially on darks) | ★★★☆☆ (Good, but can struggle on darks) |

| Feel/Hand | Noticeable layer (softer w/ WB inks) | Very soft, minimal feel |

| Cost (Low Qty) | High setup cost | Lower setup cost |

| Cost (High Qty) | Very low per-unit cost | Higher per-unit cost |

| Ink Types | Plastisol, Water-Based, Discharge | Water-Based Pigment |

- Choose Screen Printing When You Need:

- Many items (bulk orders save money)

- Simple, bold designs (clear shapes, text, solid colors)

- Super tough prints (perfect for sports uniforms & work clothes)

- Bright colors on dark shirts (ink pops on black/dark fabric)

- Special effects (metallic, puff, glitter inks)

- Choose DTG (Direct-to-Garment) When You Need:

- Very few items (even 1 shirt is affordable)

- Photo-quality details (photographs, complex artwork)

- Full-shirt designs (prints covering seams/collar)

- Soft, light feel (ink soaks into fabric, less noticeable)

- Fast samples/prototypes (quick printing for testing)

What Are The Limitations Of Screen Printing Technology?

It’s powerful, but not perfect:

- High Setup Cost & Time: Creating screens and setting up the press takes time and money. It’s not cost-effective for single items or tiny batches.

- Screen printing struggles with:

- Super tiny details or text

- Photos with smooth color blends (like soft gradients)

- Digital methods handle these much better.

- More colors = more screens = higher cost/setup.

- Ink Feel: Plastisol inks, while durable, can leave a slightly noticeable layer on the fabric. Water-based inks offer a softer hand feel but can be less opaque on darks.

- Environmental Considerations: Traditional plastisol inks are PVC-based and require careful disposal. Solvents used in cleanup also pose environmental challenges. Water-based and discharge inks offer greener alternatives.

- The Sportswear Advantage:

- Screen printing dominates athletic apparel because it withstands sweat, friction, and repeated washing.

- Performance inks (like silicone-based or stretch additives) bond with technical fabrics, maintaining moisture-wicking properties.

- Unlike some digital prints, screen prints won’t crack during high-intensity movements or after gym sessions.

Screen Printing Inks: Plastisol, Water-Based & Discharge Explained

- Plastisol: The industry standard. PVC-based, requires heat curing. Pros: Incredibly durable, opaque (great on darks), vibrant, sits on top of fabric, easy to work with. Cons: Can feel stiff/thick, not breathable, not eco-friendly (PVC/solvents).

- Water-Based: Uses water as the carrier. Pros: Much softer hand feel, breathable, more eco-friendly (no PVC, less harsh chemicals).

- Cons:

- Harder to see on dark shirts (may need white underlayer)

- Can clog screens (ink dries fast)

- Slightly less wash-proof than plastisol at first (but improving)

- Discharge: Water-based ink that removes dye from 100% cotton garments and replaces it with pigment.

- Pros: Extremely soft feel (like the original fabric), vibrant colors on darks without a thick underbase.

- Cons:

- Only works on 100% cotton (not mixed fabrics)

- Needs exact mixing and heating

- Fewer color choices

- Hybrid Ink Innovations:

- New plastisol/water-based hybrids combine durability with a softer feel.

- High-density inks create 3D textured effects popular in streetwear.

- Glow-in-the-dark and thermochromic (color-changing) inks offer creative options for limited editions.

Is Screen Printing Sustainable? Eco-Friendly Advances

The industry is evolving! Key developments address environmental concerns:

- Phthalate-Free Plastisols: Removing harmful plasticizers.

- Advanced Water-Based Inks: Offering performance closer to plastisol with a softer feel and lower environmental impact.

- LED Curing Systems: Using significantly less energy than traditional gas dryers.

- Eco-Solvents & Cleaners: Reducing VOC emissions during cleanup.

- Responsible Disposal: Increased focus on proper ink sludge and wastewater management. Brands can prioritize printers using these greener practices and inks.

- The Circular Economy Push:

- Major brands now demand recyclable printed garments.

- Water-based inks simplify fabric recycling since they don’t contain PVC.

- Closed-loop water systems in print shops reduce waste by 90%.

- Look for certifications like OEKO-TEX® or GOTS when sourcing eco-friendly prints.

The Future of Screen Printing: What’s Next?

Screen printing isn’t standing still! Innovations include:

- Automation: Advanced presses with automatic screen loading/unloading, registration, and conveyor systems boost speed and consistency.

- Hybrid Printing: Using screen printing (for base colors/whites/metallics) and DTG (for photos and fine details) on one garment to get both benefits.

- Improved Eco-Inks: Development of even higher-performing, truly sustainable plastisol alternatives.

- Digital Screen Making: Printing emulsion patterns directly onto screens with inkjet tech – makes screen creation faster and more exact.

- Smart Integration:

- Augmented reality (AR) tools now simulate print results before production.

- AI-driven color matching ensures brand consistency across batches.

- IoT-connected dryers auto-adjust temperatures for different fabrics, reducing energy waste.

Should YOU Use Screen Printing For Your T-Shirt Brand?

The answer depends on your needs:

- YES, If You need durable prints for sportswear or workwear that you’re printing bulk quantities (dozens/hundreds+). Your designs can use bold colors (especially on darks). Also cost-per-unit is a major factor, or you want to use specialty inks (metallics, foils, high-density).

- Consider Alternatives (like DTG) if… You primarily need small-batch items (or single pieces). And your design requires photorealistic elements or intricate artwork. And you prioritize a barely-there hand feel, or you demand rapid-turnaround prototypes.

- Pro Tip for Startups:

- Use DTG for initial small batches to test designs, then switch to screen printing once you hit ~30+ units per design.

- Always request print samples to check color accuracy and hand feel before bulk orders.

Understanding screen printing technology empowers you to make the best choices for your apparel line. Screen printing remains the top choice for t-shirts. And sportswear because it delivers vibrant colors, exceptional durability, and significant cost savings on bulk orders (typically 50+ pieces). Work with a printer who knows printing well – they’ll help pick inks, adjust your design, and get great results for your brand.