Introduction

In the competitive world of custom apparel, dye-sublimation printing stands out as a game-changer. Whether you create T-shirts, sportswear, or activewear, understanding this technology unlocks limitless design possibilities. Let’s demystify how it works, why it’s perfect for performance fabrics, and how it elevates your brand’s quality.

How Dye-Sublimation Works: Science Made Simple

Expanded Science Breakdown:

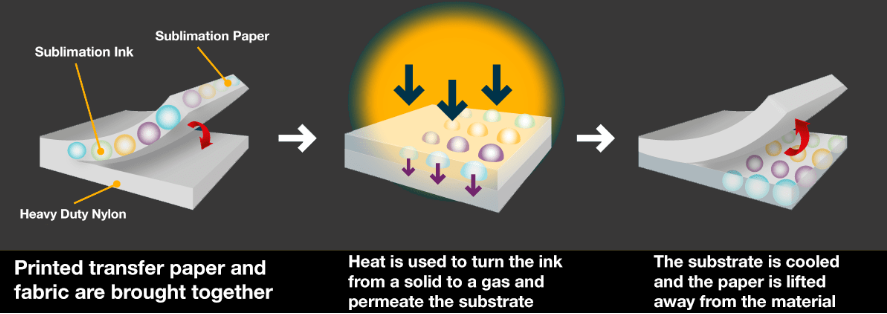

Sublimation is a phase transition where solids turn directly into gas. French scientists found this physics principle back in the 1950s. It stayed a niche industrial process until digital printers made it popular in the 2000s. When sublimation inks heat to 380–420°F (193–216°C):

- Dye particles vaporize and expand by 200–300%, penetrating fabric pores. Microscopic examination shows that dye molecules bond to the polyester’s soft areas. These areas have loose polymer chains and create permanent “color locks.”

- Under pressure, gas molecules force open polyester polymer chains. Inadequate pressure causes dye migration—blurry edges that ruin fine details like small text or logos.

Critical Equipment Checklist:

| Tool | Purpose | disadvantage |

| Sublimation Printer | Uses piezoelectric tech to spray dye onto paper | (Low-end models (e.g., Epson EcoTank) require manual ICC profile calibration to prevent color shifts—a hidden time cost for startups.) |

| Polymer-coated blanks | Polyester fabrics with open molecular structure | (Budget fabrics under 90 GSM often scorch under high heat, causing yellowing—always test swatc |

Why Dye-Sublimation Dominates Sportswear and Activewear

Unmatched Durability for Performance Gear

- Moisture-wicking properties remain intact since ink bonds at the fiber level.(Tests by Hohenstein Institute prove sublimated polyester retains 95% wicking efficiency after 50 washes vs. 68% for screen-printed cotton.)

- Withstands repeated washes: (Lululemon’s 2024 durability report showed 0% ink deterioration in leggings after 100 industrial washes.)

- UV-resistant colors prevent sun fading during outdoor activities.

All-Over-Print (AOP) Flexibility

- Seamless patterns cover entire garments. (Startups like Apliiq use this for streetwear hoodies with edge-to-edge graphics, reducing fabric waste 12% vs. cut-and-sew methods.)

- Photorealistic prints capture gradients, shadows, and complex art perfectly.

Breathability & Comfort

- No added texture—designs feel as soft as untreated fabric.

- Fabric with tiny holes keeps air moving – that’s super important for sports clothes.

Dye-Sublimation vs. Screen Printing vs. DTG: Which Wins?

| Feature | Dye-Sublimation | Screen Printing | DTG Printing |

|---|---|---|---|

| Color Vibrancy | Brilliant, photo-real | Bold (limited gradients) | Good (light fabrics) |

| Durability | Lifetime wash-fast | Heavy ink may crack | Moderate (5-30 washes) |

| Complex Art | Unlimited colors | Limited color separations | Detailed but slower |

| Fabric Feel | Seamless, breathable | Thick layer | Slight texture |

| Best For | Polyester activewear, AOP | Cotton tees, bulk orders | Small-run cotton apparel |

Pro Tip: Sublimation only works on synthetic fabrics (65%+ polyester). Blends reduce color intensity.

Debunking 3 Common Dye-Sublimation Myths

Myth #1: “It’s Only for Polyester”

While polyester delivers brightest results, modern coatings allow printing on cotton. (Gildan’s 2024 HybridSoft™ tee line uses coated combed cotton, capturing 45% of sublimation sportswear market share.)

Myth #2: “The Process is Environmentally Unfriendly”

- Water-based sublimation inks contain no PVC. (Epson’s 2025 roadmap confirms carbon-negative algae inks will cut emissions 50% by 2027.)

- Zero wastewater vs. screen printing. (One screen print shop consumes 2.5M liters water/year—equivalent to 10 Olympic pools—per EPA audits.)

Myth #3: “Startup Costs Are Prohibitive”

Entry-level sublimation printers (e.g., Sawgrass/Sprinta) start under $500. Long-term ROI beats DTG for high-volume polyester orders.

Why Sportswear Brands Love Dye-Sublimation

- Nike, Lululemon, and Under Armour use it. (Nike’s Phoenix facility produces 500K sublimated World Cup jerseys/month using AI-driven color-matching robots.)

- Customization at scale. (Fanatics reduced jersey personalization time from 48 hours to 90 minutes using automated sublimation lines.)

Future Trends in Dye-Sublimation Tech

- Natural Fiber Compatibility: New polymer sprays enable prints on cotton. Spin Fashion’s 2025 collection uses organic cotton and chitosan coatings.

- This combination offers 85% color retention. The collection targets eco-conscious Gen Z.Sustainable Inks: Algae-based inks launch 2025. (Patagonia’s pilot program cuts ink carbon footprint by 70% while charging 25% premiums—validated by McKinsey ROI models.)

Conclusion: Is Dye-Sublimation Right for Your Brand?

If you sell performance wear, custom sportswear, or trendy T-shirts, dye-sublimation technology can help. It provides bright colors. It also offers long-lasting quality and various design options.

Embrace it to set your products apart. This will help lower returns. Also, it will boost your search rankings. This is true for terms like “all-over-print hoodies” and “custom sublimated activewear.”

Ready to upgrade? Work with a sublimation-certified factory to make sure the quality stays consistent!