Custom T-shirts are a great way to promote your brand or create unique products. Whether for retail, wholesale, or as promotional items, ensuring your custom T-shirts are durable and look good for a long time is key.

1. Screen Printing vs. DTG Printing: What’s Best for You?

- Screen Printing: This method is ideal for large orders. It uses stencils to apply ink onto the fabric, producing vibrant colors and durable designs. Screen printing is cost-effective for bulk orders.

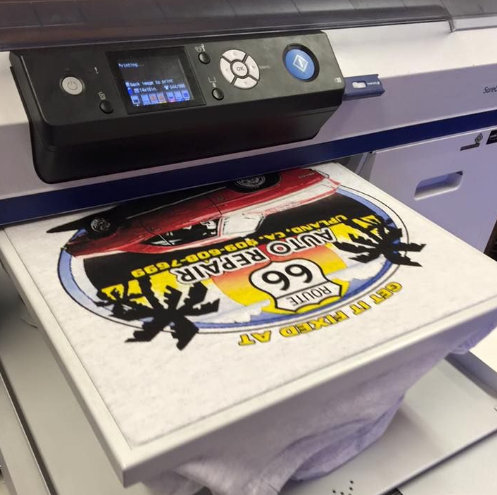

- DTG (Direct-to-Garment) Printing: This method uses an inkjet printer to print designs directly onto the fabric. It’s great for small batches and intricate designs with lots of color details. It’s perfect for custom T-shirts with unique, high-quality prints.

2. Factors That Affect T-Shirt Durability

- Fabric Choice: Use high-quality fabrics, like 100% cotton or cotton-polyester blends, to ensure prints last longer.

- Print Quality: Both screen printing and DTG printing require the right ink for durability. Choose inks that are specifically designed for fabric to avoid cracking or fading.

- Care Instructions: Proper washing and drying are essential. Both screen-printed and DTG T-shirts need specific care to keep designs looking fresh.

3. How to Ensure Durable Screen Printed T-Shirts

- Step 1: Choose the Right Ink: Use plastisol ink for vibrant colors and long-lasting prints. Water-based inks are softer but may not last as long.

- Step 2: Pre-Treat the Fabric: Pre-wash the T-shirts to remove chemicals and prevent shrinking.

- Step 3: Curing the Ink: Proper curing ensures the ink bonds well with the fabric. Use a heat press or inkjet printer to cure the ink at the right temperature.

- Step 4: Test for Durability: Before mass production, test the print on a few shirts to ensure it holds up after washing.

4. How to Ensure Durable DTG T-Shirts

- Step 1: Use a Quality DTG Printer: A high-quality DTG printer will give you vibrant colors and precise prints.

- Step 2: Pre-Treat the Fabric: Use a special solution to pre-treat the fabric, ensuring the ink lasts longer.

- Step 3: Use the Right Inks: Choose water-based inks designed for DTG printing to avoid fading or peeling.

- Step 4: Cure the Ink: Proper curing is essential. Follow the manufacturer’s guidelines for the correct curing time and temperature.

5. Which Method Should You Choose?

- For Bulk Orders: If you need a large number of T-shirts, screen printing is the best option. It’s cost-effective and produces durable prints.

- For Small Batches or Intricate Designs: DTG printing is ideal for smaller runs or more complex designs with lots of colors.

6. Tips for Long-Lasting Custom T-Shirts

- Use High-Quality Fabrics: Choose 100% cotton or cotton/polyester blends that hold prints well.

- Consider Fabric Weight: Heavier fabrics usually last longer and can withstand more wear and tear.

- Work with Professional Manufacturers: Partner with experienced manufacturers like Cekno offering durable, high-quality custom T-shirts with expert screen printing and DTG printing, along with full OEM/ODM services for custom designs, fabrics, and packaging. With eco-friendly materials, fast turnaround, competitive pricing for bulk orders, and excellent customer support, you can expect vibrant, long-lasting prints.

Conclusion

To create durable, high-quality custom T-shirts, you need the right printing method, fabric, and care. Whether you choose screen printing or DTG printing, make sure to invest in quality materials and work with a trusted manufacturer like Cekno. With the right approach, your custom T-shirts will last for a long time and look great.