Which printing method is most suitable for mass production of clothing? Flat screen printing is a classic technique still widely used for bulk orders of T-shirts, hoodies, and children’s clothing.

Flat screen printing is a traditional method that uses a scraper to apply color paste through a flat screen onto fabric. Compatible with cotton, poly-cotton, and more, it delivers bold, high-quality prints—perfect for high-volume clothing orders.

Do you want to learn more about the differences between it and other printing methods? Here are some practical things to know before placing an order.

What is the difference between flat screen printing and round screen printing?

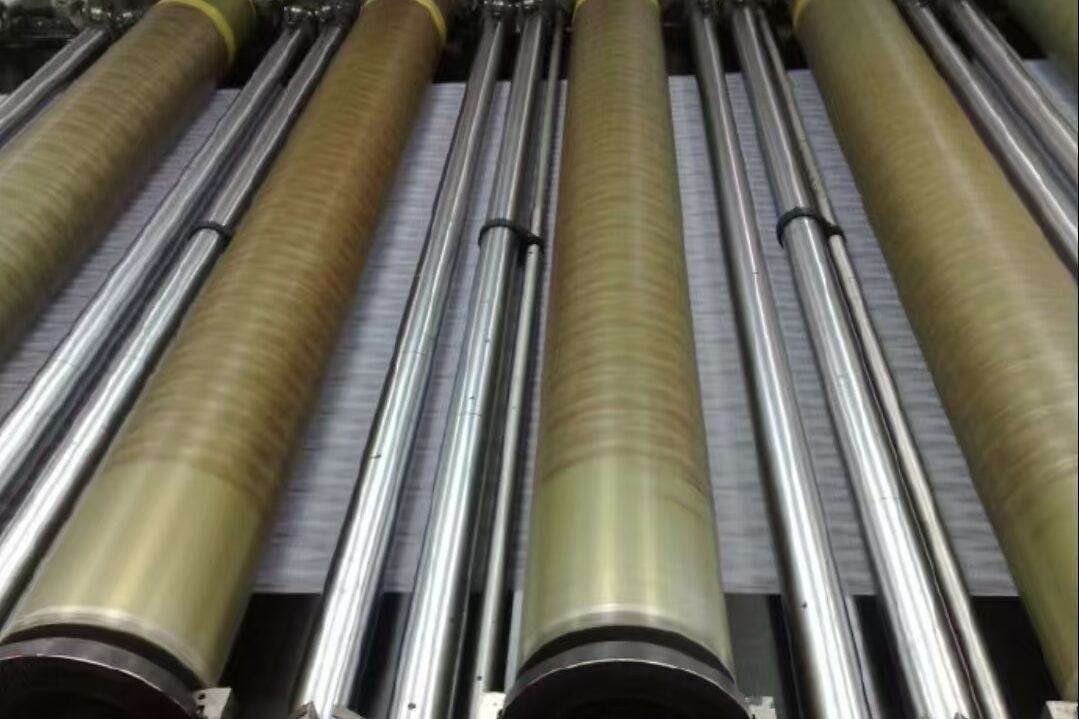

Flat screen printing involves applying ink through a flat screen using a manual or mechanical scraper. It delivers excellent results for bold, oversized graphics with precise color fidelity. Round screen printing uses a drum type screen plate, which is suitable for large-scale and fast printing on assembly lines.

In short:

- Flat screen: High precision, moderate efficiency, suitable for detailed patterns

- Round mesh: fast speed, low cost, suitable for large batch orders

If you have higher requirements for patterns or want customized printing, flat screen printing is more suitable.

What are the advantages and Drawbacks of flat screen printing?

advantage:

- The pattern has bright colors and good coverage

- Clear printing details and neat edges

- High stability, suitable for long-term repeated printing

- Especially suitable for mass production of common clothing such as T-shirts, hoodies, etc

Drawbacks:

- Relatively low efficiency

- Each pattern change requires redoing the screen, resulting in slightly higher plate making costs

- The process flow is complex and requires high experience

What fabrics are suitable for flat screen printing?

Flat screen printing has strong Flexibility and is suitable for the following types of fabrics:

- Cotton fabric, polyester cotton blend fabric

- Polyester, nylon and other synthetic fabrics

- Natural materials such as silk and linen

- Elastic fabrics such as spandex and Lycra

Different fabrics can affect the printing fastness and coloring effect. Providing fabric samples for test printing is strongly advised before making a purchase decision.

How to choose the appropriate printing technique?

This depends on the following aspects:

- Pattern complexity: It is recommended to use flat screen or digital printing for complex patterns

- Fabric type: Polyester fabric suitable for sublimation, cotton fabric suitable for flat mesh or direct spray

- Order quantity: For bulk orders, we recommend flat or round mesh printing. For small batches, we can choose heat transfer printing or digital printing

- Budget and delivery time: The flat net process is stable and suitable for controlling costs and time

What is the process of flat screen printing?

A complete flat screen printing process includes the following steps:

- Draft Design and Color Separation

- Making screen printing (sun drying)

- Mixing specialized colorants

- Manual or mechanical scraping printing

- Drying/fixing treatment

- Post finishing process (such as washing and shaping)

Understanding this process can help you evaluate delivery time and pricing reasonably.

What is the difference between screen printing and heat transfer printing?

| Project | Screen Printing (Flat Screen Printing) | Heat Transfer Printing |

| Process principle | Ink is screen printed onto the fabric through a scraper | Pattern is transferred from paper to fabric through high-temperature hot pressing |

| Cost | High initial plate making cost, suitable for large quantities | Suitable for small batches, high single piece cost |

| Fastness | High, washable and durable | Easy to peel off, average fastness |

| Effect | Can achieve large-area, full-color patterns | Exquisite patterns have good expressive power, but are prone to wrinkling |

If you plan to produce a certain product in the long term, choosing silk screen printing is more secure.

Where can I find a reliable printing factory?

Are you looking for reliable, fast turnaround, and fully customized batch printing? Visit their factory website to learn more:https://ceknoclothing.com/

With years of experience in flat screen printing, we offer printing on a wide range of fabrics including cotton and blends. We have served numerous clothing brands and provide one-stop services such as sample testing, bulk production, and fast shipping.

summarize

Flat screen printing is still one of the mainstream choices for bulk clothing printing at present. Ready to place a bulk order or find a stable long-term production partner? Click the link below to contact us today.We will provide fast sampling and accurate quotation services!