Looking to create custom T-shirts with vibrant, full-color designs but not sure which printing method to go for? Whether you’re a wholesaler, retailer, or B2B buyer, choosing the right print method can make a huge difference in both the quality of your shirts and your bottom line.

In this post, we’ll break down the most popular printing techniques so you can find the best fit for your needs — no matter how big or small your order is!

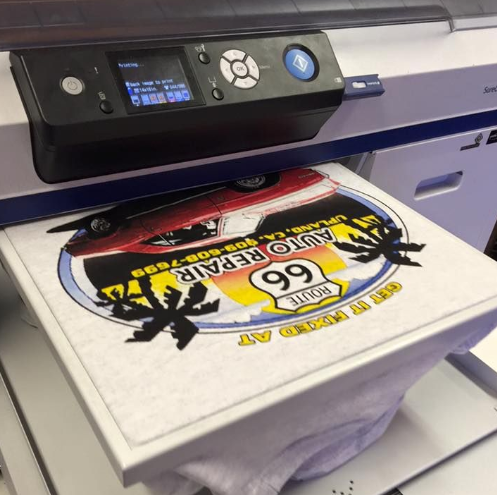

1. Direct-to-Garment (DTG) Printing

Best For: Small to medium runs with detailed full-color designs.

Why It Works:

- High detail: DTG is perfect for intricate, multicolored designs.

- Vibrant colors: The technology uses water-based inks, which absorb into the fabric for a vibrant finish.

- Eco-friendly: Fewer chemicals and waste than traditional printing methods.

Limitations:

- Not ideal for large orders due to slower print times.

- Works best on 100% cotton or cotton-blend fabrics.

2. Screen Printing

Best For: Large orders with limited colors.

Why It Works:

- Durability: Known for its long-lasting prints.

- Cost-effective: The price per unit decreases as the order volume increases.

- Vibrant colors: Excellent for bold designs and single-color prints, but can be used for multi-color with more screens.

Limitations:

- Not ideal for designs with many colors or gradients.

- Requires setup time and screen creation for each design.

3. Sublimation Printing

Best For: All-over designs on polyester fabrics.

Why It Works:

- Full-color printing: Sublimation allows for vibrant, high-resolution designs with no limits on the number of colors.

- All-over designs: Perfect for covering the entire T-shirt, including seams.

- Long-lasting: Prints are embedded into the fabric, making them resistant to fading or peeling.

Limitations:

- Works only on polyester or poly-blend fabrics.

- Not suitable for cotton-based T-shirts.

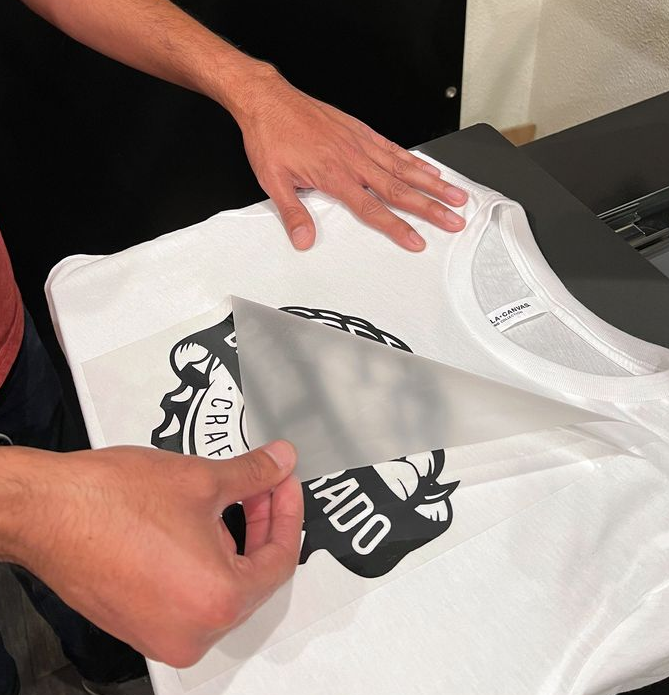

4. Heat Transfer Printing

Best For: Small batches or custom designs.

Why It Works:

- Quick turnaround: Ideal for fast production with less setup.

- Versatile: Can be used on a variety of materials and fabrics, including cotton and polyester.

- Vibrant color reproduction: Especially good for full-color designs and complex images.

Limitations:

- Prints may fade after multiple washes.

- Not as durable as screen printing or sublimation for long-term use.

5. Vinyl Printing

Best For: Simple, bold designs with fewer colors.

Why It Works:

- Durability: Vinyl prints are long-lasting and resistant to peeling or cracking.

- Great for small designs: Works well for logos, numbers, or simple graphics.

Limitations:

- Limited color range compared to other methods.

- Best suited for designs with fewer colors or solid shapes.

6. Pigment Printing

Best For: Designs requiring vibrant colors and quick production.

Why It Works:

- Bright prints: Ideal for high-quality, full-color designs.

- Quick drying: The pigment ink sets quickly, speeding up production time.

Limitations:

- Not as durable as other methods like screen printing for mass orders.

Summary:

When choosing the best printing method for your T-shirt designs, consider the volume of your order, the fabric type, and the level of detail in your artwork. Here’s a quick recap of each method:

- DTG Printing: Best for detailed, small to medium runs on cotton.

- Screen Printing: Ideal for large quantities with limited colors.

- Sublimation: Best for all-over prints on polyester fabrics.

- Heat Transfer Printing: Good for small batches with full-color designs.

- Vinyl Printing: Great for simple, bold designs.

- Pigment Printing: Quick drying and bright, but less durable.

By understanding these methods, you’ll be able to select the best option for your T-shirt orders, ensuring quality, efficiency, and customer satisfaction.