Why Durable Prints Matter in the B2B Market

As a retailer or wholesaler, ensuring your custom tri-blend t-shirts maintain their quality is essential for long-term customer satisfaction. Prints that fade, crack, or peel not only result in dissatisfied customers but also create added costs for returns, replacements, or damaged reputation.

This guide will show you the best practices for achieving durable, high-quality prints on tri-blend t-shirts, along with tips for maintaining their longevity, ensuring your business delivers exceptional value with every order.

What Makes Tri-Blend T-Shirts Unique for Custom Printing?

Tri-blend t-shirts are a popular choice in retail and wholesale markets because of their superior feel and performance:

- Fabric Composition: A mix of cotton, polyester, and rayon creates a fabric that is:

- Soft: Smooth and lightweight, perfect for premium apparel.

- Durable: Polyester improves strength, while rayon provides stretch and recovery.

- Moisture-Wicking: Great for activewear or streetwear markets.

- Challenges with Printing: The polyester and rayon content in tri-blends makes them heat-sensitive, which requires careful consideration during the printing process.

Best Printing Methods for Tri-Blend T-Shirts

Choosing the right printing technique is crucial for maintaining both print quality and fabric integrity. Here are the top methods suitable for tri-blend fabrics:

1. Sublimation Printing

- How It Works: Dyes are infused directly into the polyester fibers.

- Why It’s Ideal: Sublimation creates vibrant, fade-resistant prints that are lightweight and long-lasting.

- Best Use: Light-colored or white tri-blend shirts with a higher polyester content.

- Consideration: Not suitable for dark fabrics.

2. Screen Printing

- How It Works: Ink is layered onto the fabric through a stencil, creating bold designs.

- Why It’s Ideal: Screen printing produces durable, long-lasting prints that hold up well after repeated washes.

- Best Use: Large logos, bold designs, and high-volume orders.

- Consideration: Use low-cure inks to prevent fabric scorching.

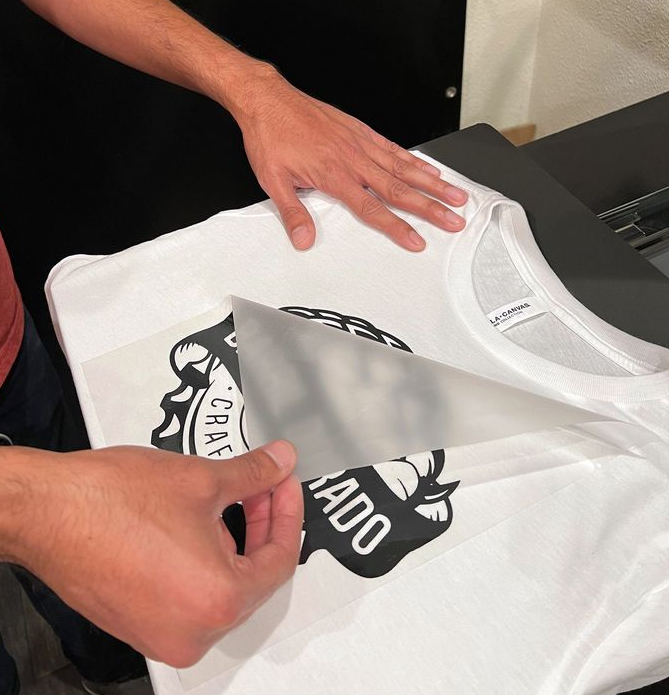

3. Heat Transfers

- How It Works: Pre-printed designs are applied using heat and pressure.

- Why It’s Ideal: Heat transfers are cost-effective for small batches or custom designs.

- Best Use: Budget-friendly orders with simple graphics.

- Consideration: Requires low-temperature settings to avoid fabric damage.

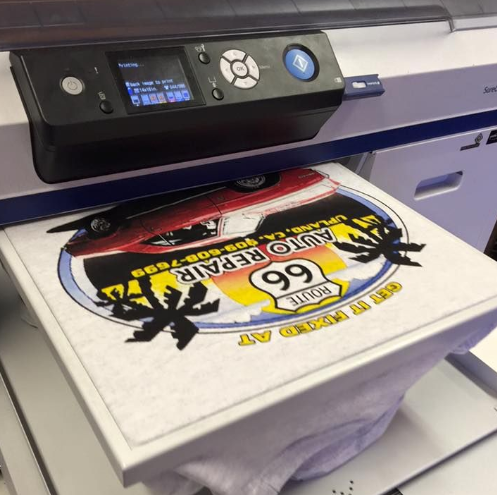

4. Direct-to-Garment (DTG) Printing

- How It Works: A printer applies ink directly onto the fabric, like an inkjet printer.

- Why It’s Ideal: DTG is excellent for detailed, multi-color designs on tri-blend t-shirts.

- Best Use: Limited runs of high-detail graphics.

- Consideration: Can be costly for large-scale orders.

Tips for Heat-Press Printing on Tri-Blend T-Shirts

If you’re using heat presses for your tri-blend garments, follow these tips to ensure the best results:

- Use Low-Cure Inks: Prevent dye migration and fabric scorching.

- Test Settings: Adjust temperature, pressure, and time to avoid heat damage.

- Pre-Treat Fabrics: Use a pre-treatment solution to ensure the design adheres evenly.

- Avoid Over-Pressing: Excessive heat and pressure can leave shiny marks on the fabric.

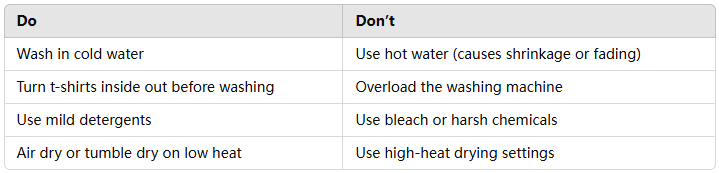

Caring for Printed Tri-Blend T-Shirts

Help your customers maintain the quality of their printed tri-blend t-shirts by providing clear care instructions.

Do’s and Don’ts of Caring for Printed Tri-Blend T-Shirts

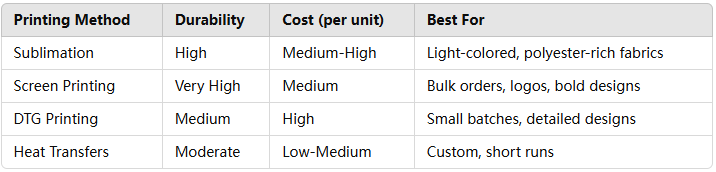

Cost vs. Durability: Printing Methods Compared for B2B Buyers

Here’s a breakdown of the most common printing methods, focusing on their durability, cost-effectiveness, and scalability for wholesale orders:

Conclusion

For B2B buyers, achieving long-lasting prints on tri-blend t-shirts requires a combination of selecting the right printing method and following proper care techniques. Sublimation and screen printing offer superior durability, while heat transfers and DTG are ideal for specific needs. By educating your customers on proper care, you can reduce complaints and increase repeat business.

Ready to enhance your product offerings with durable, high-quality printed tri-blend t-shirts? Let’s make it happen!