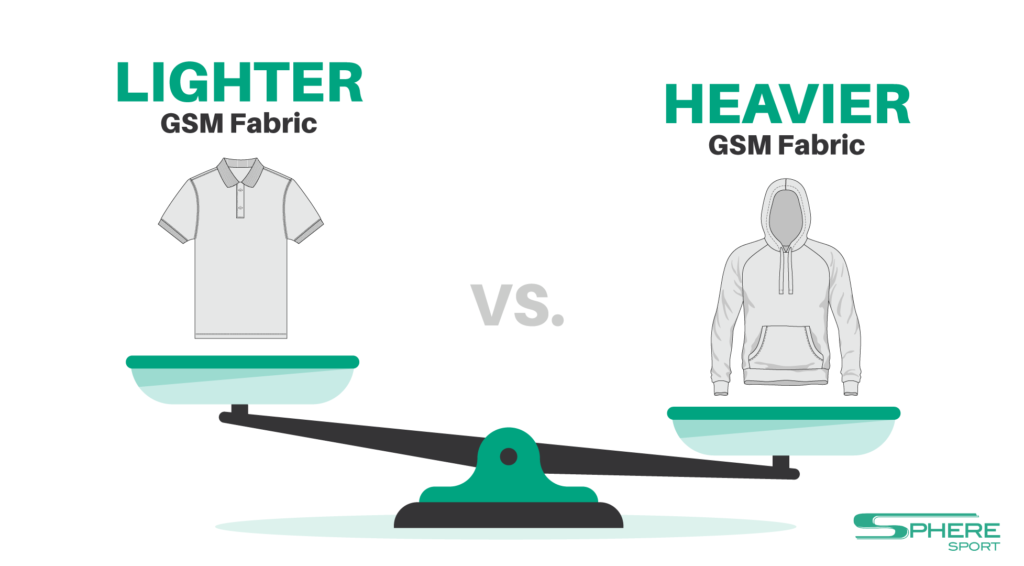

Fabric density is a key factor in determining the performance, feel, and durability of custom T-shirts and hoodies. When selecting fabrics for custom apparel, it’s important to understand how fabric density, typically measured in grams per square meter (GSM), influences various aspects of the garment. This article explores the role of fabric density in custom clothing manufacturing, providing insights for wholesalers, retailers, and brand owners.

1. What Is Fabric Density?

Fabric density refers to the weight and thickness of the fabric, typically quantified by its GSM. It is a critical metric that helps determine the fabric’s weight and structural properties.

- High GSM (200-300 GSM): Thicker, heavier fabrics suited for colder weather garments such as hoodies and sweatshirts.

- Low GSM (120-180 GSM): Lighter, more breathable fabrics ideal for warmer climates and lighter apparel like T-shirts.

2. The Impact of Fabric Density on Comfort

Fabric density has a direct impact on how comfortable a garment feels against the skin. Depending on the fabric’s GSM, the clothing can either feel light and airy or heavy and insulating.

- Higher GSM Fabrics: These fabrics are typically heavier and provide a soft, cozy, and insulating feel. They are commonly used in hoodies and sweatshirts that are designed to provide warmth and durability.

- Lower GSM Fabrics: These fabrics are lighter and more breathable, making them ideal for T-shirts and other lightweight garments, offering comfort during warm weather.

3. Durability and Longevity

- High GSM Fabrics: Thicker fabrics are more resistant to damage from frequent washing, stretching, and fading. They retain their shape better over time and provide longer-lasting performance.

- Low GSM Fabrics: While soft and comfortable, lighter fabrics are more susceptible to damage and may show signs of wear more quickly, especially after frequent use or washing.

4. The Effect on Print Quality

- High GSM Fabrics: Thicker fabrics generally provide a smoother surface for printing, leading to sharper, more vibrant designs. The increased fabric density helps the print adhere better and last longer.

- Low GSM Fabrics: While suitable for light prints or simple designs, thinner fabrics may cause prints to fade more quickly and may not retain intricate details as well as higher-density fabrics.

5. Seasonal Suitability

Choosing the right fabric density is essential for creating garments suited for specific seasons:

- Heavy Fabrics (200-300 GSM): These fabrics are ideal for winter or fall garments, providing the necessary insulation and warmth for cold-weather clothing like hoodies and sweatshirts.

- Light Fabrics (120-180 GSM): Perfect for summer T-shirts or spring jackets, these fabrics provide comfort without causing overheating.

6. Fabric Fit and Structure

- Heavier Fabrics: Typically provide a more structured, formal fit. These fabrics hold their shape well and are ideal for tailored or less casual designs.

- Lighter Fabrics: Offer more flexibility and tend to drape loosely, which makes them more suitable for casual, relaxed fits often seen in streetwear and activewear.

7. Cost Implications

- Higher GSM Fabrics: Due to their thickness and durability, these fabrics are more expensive. They are commonly used for higher-end products that require a premium feel.

- Lower GSM Fabrics: More cost-effective and ideal for large, bulk orders where price is a significant consideration, but they may not offer the same longevity as higher-density fabrics.

8. Fabric Density and Sustainability

Lighter fabrics with lower GSM are often seen as more sustainable options, especially when made from eco-friendly materials. These fabrics require fewer resources to produce and are often used for more environmentally conscious brands.

However, denser fabrics, if sourced from sustainable materials and manufactured responsibly, can also contribute to a sustainable fashion cycle by offering long-lasting durability.

9. Common Fabrics and Their GSM Ranges

- Cotton: 180-220 GSM (a popular choice for custom T-shirts and hoodies, offering comfort and breathability).

- Polyester: 120-200 GSM (ideal for activewear and lightweight garments due to its moisture-wicking properties).

- Blends (Cotton/Polyester): 150-220 GSM (providing a balance between comfort, durability, and breathability).

- Fleece: 200-300 GSM (a thicker fabric often used for winter sweatshirts and hoodies).

10. How to Choose the Right Fabric Density

- Garment Purpose: Determine whether the garment needs to provide warmth, be lightweight and breathable, or have durability for repeated use.

- Branding Needs: For premium brands, higher-density fabrics might be preferred for their durability and luxurious feel. For budget-conscious options, lighter fabrics may be more appropriate.

- Target Market: Consider the climate and preferences of your target market. For colder regions, denser fabrics will provide necessary warmth, while lighter fabrics work well for warmer climates.

Conclusion

Understanding fabric density is crucial for selecting the right T-shirts and hoodies for your custom clothing needs. From comfort and durability to print quality and seasonal suitability, the fabric’s GSM has a significant impact on the final product. Choosing the right fabric density allows you to strike a balance between quality, performance, and cost.